AutoFoam

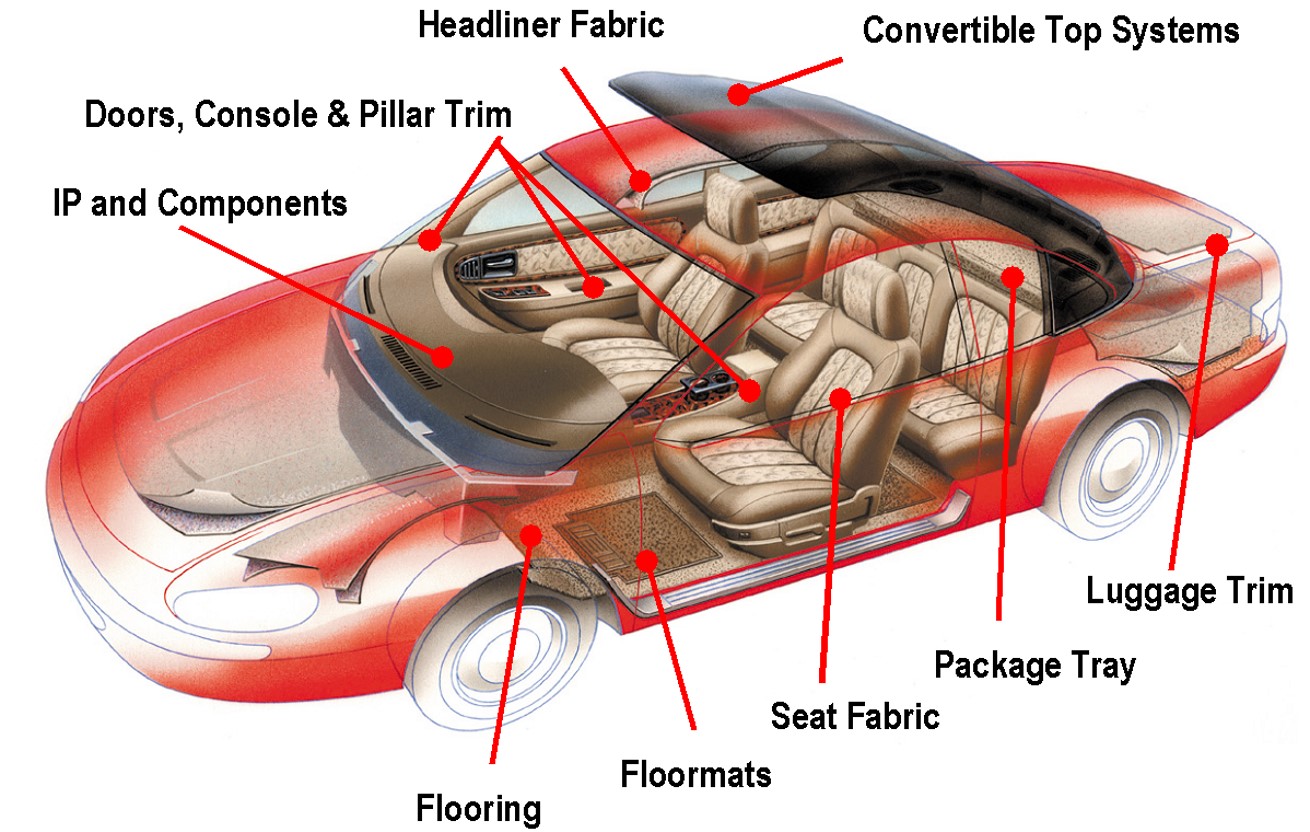

AutoFoamTM predicts the acoustical performance of noise control treatments consisting of structural, acoustic (fluid/Air) and poroelastic layers. It aslo estimates the poroelastic, macroscopic material properties of various noise control treatments from measured sound transmission loss, absorption coefficient and a combination of those measured performance metrics. Additionally, the importance of the material properties on the performance can be determined using the contribution analysis feature of the software.

-

Efficient Solutions for planar noise control treatments

Based on analytical solutions that do not require tedious modeling of the layers. It only requires the layer type, layer configuration, material properties and thickness of each layer as input.

-

Multiple Solutions Methods

Multiple solution options, including transfer matrix method for bonded and unbonded multi-layer treatments and four-pole method for exact representation of unbonded layers are available. The effect of finite size is also considered in the prediction.

-

Extensive Analysis Capabilities

Predicts acoustical performance such as sound transmission loss and absorptions coefficient. Estimates macroscopic material propeties of a wide variety of material combinations.

-

Broad material library

Models a wide variety of materials such as elastic foam, rigid foam, limp foam, fibrous foam, impervious screen, resistive screen, elastic solid, elastic, panel, and perorated screen.

-

Acoustic Characterization

Predicts normal and random incidence acoustic characteristics of single and multilayer noise control treatments.

-

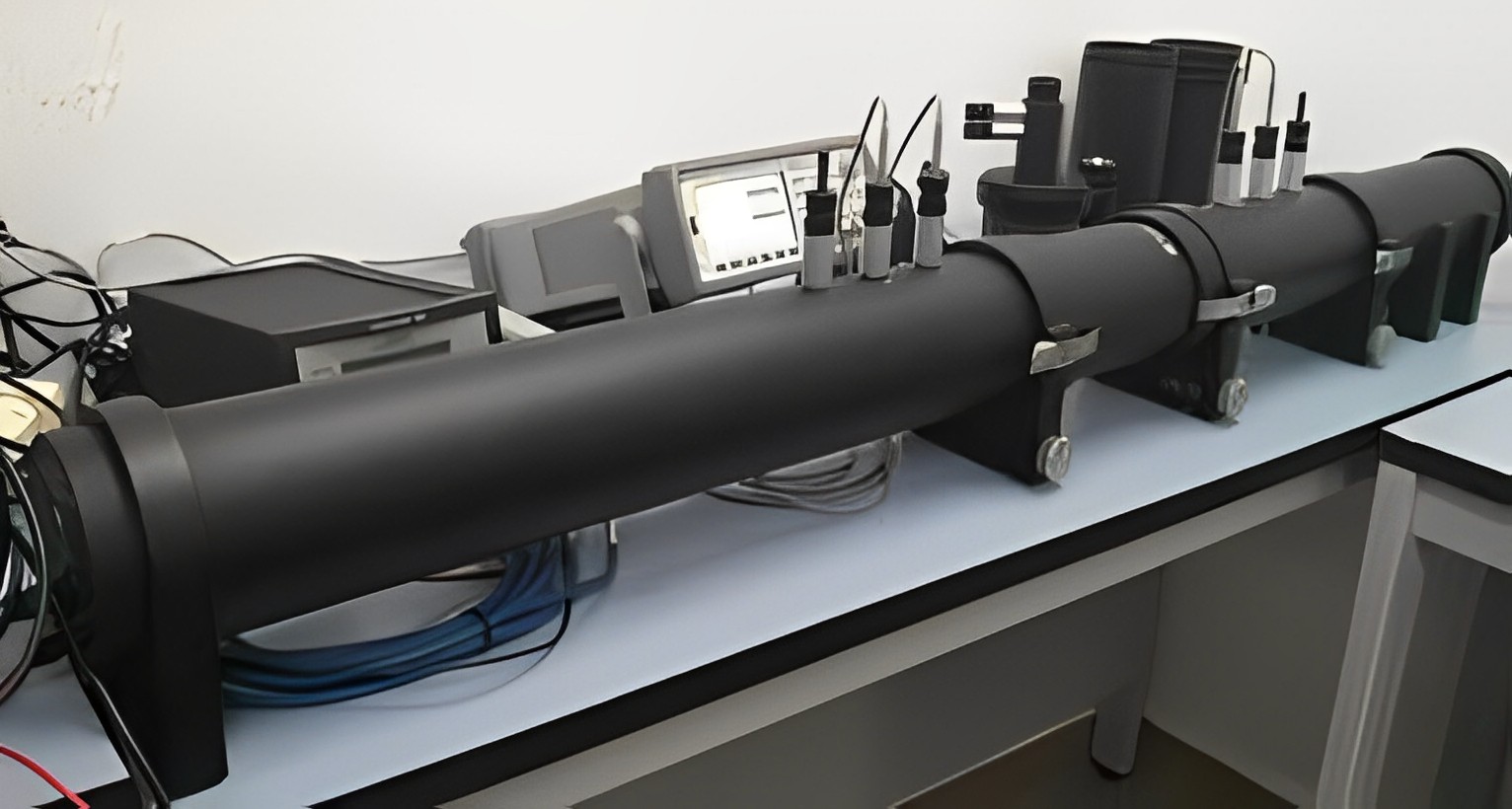

Material Characterization

Estimates macroscopic material properties of a wide variety of single and multi-layer noise control treatments using measured absorption and/or transmission loss data.

An advanced feature uses the exact representation of impedance tube for enhanced evaluation of mechanical properties of poroelastic materials.

-

Contribution analysis

Computes relative importance of material properties on the acoustical performance through a scaling process.

Comet EnFlow

Comet EnFlowTM is an advanced analysis software forfull frequency simulation of dynamic systems based on wave methods for low frequency simulation and energy flow concepts for high frequency simulation. As an alternative to Statistical Energy Analysis (SEA), Energy Flow Analysis (EFA) utilizes traditionally used finite element method (FEM) and boundary element method (BEM) for the solution of vibroacoustic problems.

In EnFlow, both the structural and acoustic domains are modeled using finite elements and at the interface of geometric and material discontinuities, joint elements based on power flow continuity across the junction is utilized. It also utilizes boundary BEM for the modeling of both interior and exterior acoustic domains, thereby eliminates the tedious task of domain discretization.

By giving you a beter understanding of the noise your products will make, Comet EnFlow helps you refine your design - before investing in costly physical prototypes.

-

Ease of Modeling

Full frequency virtual acoustic simulation of dynamic systems using the same modeling framework. Conventional finite elememt meshes that are readilly available can be used directly for both low and high frequency solutions, although 'fine' mesh is not required for high frequency simulation.

-

Optimal Design of Structural Components and Noise Control Treatments

Systematic analysis and design improvement at early states of product development without the need to rely on costly physical prototypes. It provides an overall approach to sound management by considering sound propagation, radiation and transmission in a variety of media including fluid, solids and (poroelastic) noise control treatments.

-

Intuitive modeling that requires less user expertise and experience

Unlike alternative methods such as SEA, EFA requires less user expertise to create models.Finite element models for modeling dynamic systems are easily derived from models that are typically used for many other engineering analyses.

-

Comprehensive Analysis Capabilities

- Frequency response analysis at discrete frequencies.

- Prediction of transmission loss.

- Interior and exterior modeling.

-

Coupling of Multiple Media

- Modeling of fluid, solid and noise control domains.

- Automated generation of joints, including joints at noise control treatments.

-

Extensive Element Libraries

Acoustic element, structural elements including rods and beams, isotropic and orthotropic plates, and honeycomb (sandwich). Noise control treatments (NCT) including elastic foam, rigid foam, limp foam, fibrous foam and perforated panels.

-

Enhanced Capabilities

Modeling of leakage, conservative and non-conservative joints, local damping and direct field excitations, and user-defined elements and joints.